A WPS is a document that describes how weldingis to be carried out in production. They are recommended for allwelding operations and many application codes and standards make them mandatory

What information should they include?

Sufficient details to enable any competent personto apply the information and produce a weld of acceptable quality. The amount of detail and level of controls specified on a WPS is dependanton the application and criticality of the joint to be welded.

For most applications the information required isgenerally similar to that recorded on a Procedure Qualification Record(PQR) or Welding Procedure Approval Record (WPAR), except that ranges areusually permitted on thicknesses, diameters, welding current, materials,joint types etc.

- WPS' drug prior authorization program supports evidence-based treatment and is intended to optimize the care provided by practitioners to our customers. Drugs subject to prior authorization may have specific safety issues, may require a higher level of care coordination, may compete with other products that offer similar or greater value,.

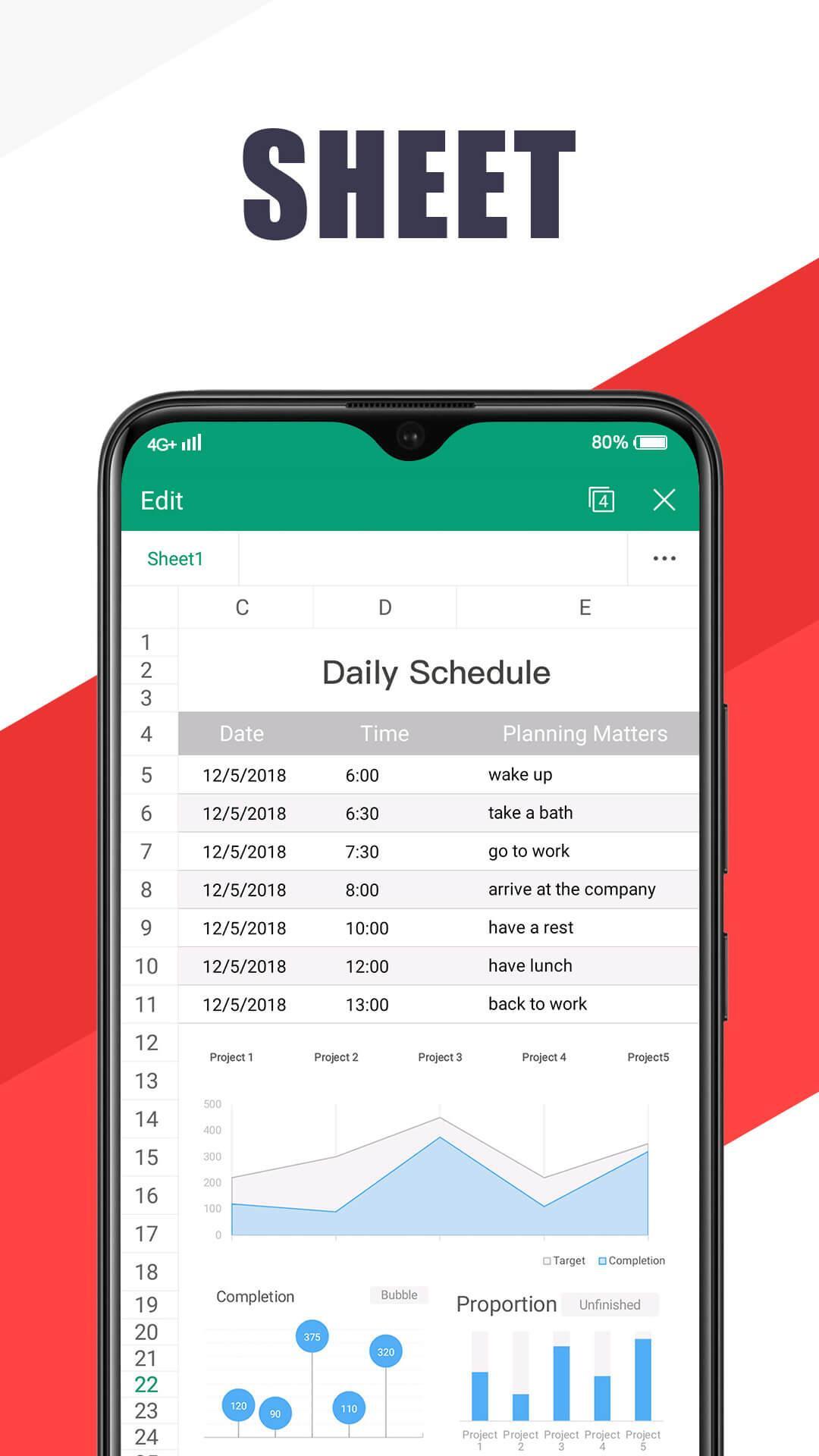

- WPS Office is the smallest size (less than 37MB) and all-in-one complete free office suite on Android mobile and tablets, integrates all office word processor functions: Word, PDF, Presentation.

Free Downloads ANSI Z49.1:2012, Safety in Welding, Cutting, and Allied Processes. The American Welding Society's Board of Directors has decided that ANSI Z49.1 should be distributed freely, as it is an important voluntary welding safety and health standards document.

If a WPS is used in conjunction with approved weldingprocedures then the ranges stated should be in accordance with the approvalranges permitted by the welding procedure.

However careful consideration should be given tothe ranges specified to ensure they are achievable, as the ranges givenby welding procedure standards do not always represent good welding practice. For example welding positions permitted by the welding procedure standardmay not be achievable or practical for certain welding processes or consumables.

EN ISO 15609-1 (formally EN 288 Part 2) European Standard ForWelding Procedure Specifications

EN ISO 15609 Defines the contents of a WeldingProcedure Specification in the form of a list of information that shouldbe recorded. For some applications it may be necessary to supplementor reduce the list. For example only in the case of a procedure requiringheat input control would there be a necessity to quote travel speed orrun-out length for manual processes.

ASME IX American Boiler and PressureVessel Code

QW 250 Lists the variables for each welding process,all the variables stated should be addressed. The range permittedby the WPS is dictated by the PQR or PQR’s used to qualify it.

Typical Items That Should Be Recorded On W.P.S:-

Common to all Processes .

- Procedure number

- Process type

- Consumable Size, Type and full Codification.

- Consumable Baking Requirement if applicable

- Parent material grade and spec.

- Thickness range.

- Plate or Pipe, Diameter range

- Welding Position

- Joint Fit Up, Preparation, Cleaning, Dimensions etc.

- Backing Strip, Back Gouging information.

- Pre-Heat (Min Temp and Method)

- Interpass If Required (Maximum Temperature recorded )

- Post Weld Heat Treatment. If Required (Time and Temp)

- Welding Technique (weaving,max run width etc.)

- Arc Energy Limits should be stated if impact tests are requiredor if the material being welded is sensitive to heat input.

| Specific To Welding Processes | MMA | TIG | MIG MAG FCAW | SUB ARC |

| Welding current | yes | yes | yes | yes |

| Type of Welding current AC/DC Polarity | yes | yes | yes | yes |

| Arc voltage | If Auto | yes | yes | |

| Pulse parameters (Pulse time and peak & backgound current) | If Used | If Used | ||

| Welding Speed If Mechanised | yes | yes | yes | |

| Wire configuration | yes | |||

| Shielding gas (comp,flow rate) | yes | yes | ||

| Purge gas (comp & flow rate) | If Used | If Used | ||

| Tungsten electode Diameter and type. | yes | |||

| Nozzle diameter | yes | yes | ||

| Type of Flux Codification & Brand Name | yes | |||

| Nozzle Stand Off Distance (Distance from tip of nozzle to workpiece). | yes |

Getting over it. Sketches

A sketch of the joint configuration is required whichshould include the basic dimensions of the weld preparation. Someindication of the run sequence is also beneficial, particularly if thecorrect sequence is essential to ensure the properties of the weld aremaintained.

Production Sequence

Whilst this is good practice it is not a requirement of either

Non Destructive Testing

A WPS is primarily concerned with welding not N D T, this activity should be covered by separate N D T procedures.

WPS and PQR Demystified

- Feb 1, 2018 03:15 PM

Several members of the Education Services team at AWS recently had the opportunity to attend a handful of instructor-led CWI seminars. During that time, we were able to interact with the students and get some insight into how things were going for them. Collectively, we found that most students were at least somewhat familiar with the majority of the information that was being covered during the seminar. However, there was one topic that drew a complete blank from students time and time again: Welding Procedure Specifications and Procedure Qualification Records.

“What is a WPS?” “What is a PQR?” “Why are they important?” “How do I use them?”

If these questions have you shrugging your shoulders as well, don’t worry, we’re about to break these confusing acronyms down for you a bit. Building on our popular four-part Welding Symbols Demystifiedseries (Part I,Part II,Part III,Part IV), let’s tackle WPSs and PQRs.

What is a WPS?

A Welding Procedure Specification, or WPS, is a document that serves as a guide for the effective creation of a weld that meets all applicable code requirements and production standards. Think of a WPS as a recipe for welders. In the same way that a recipe for a cake details what ingredients and quantities you’ll need, a WPS contains details that are necessary to create the desired weld. This includes information such as base metal grade, filler metal classification, amperage range, shielding gas composition, and pre-heat and interpass temperatures. The idea is that if a group of welders adhere to all the details on a WPS, they should each be able to produce welds with reasonably similar mechanical properties. Advanced uninstaller pro freeware.

What is a PQR?

To answer this question, we need to take a step back. You see, before a WPS can be drafted, a preliminary set of procedures and materials must be established. This initial procedure is used to create a series of welds which are then mechanically tested to ensure they meet all applicable requirements. The procedures for creating and testing the sample welds, as well as the final results, are documented on a Procedure Qualification Record, or PQR. If the test results are acceptable, the PQR is approved and can then serve as the foundation on which one or more WPSs are drafted. In short, a PQR serves as evidence that a given WPS can, in fact, be used to produce an acceptable weld.

What's the Importance of a WPS and PQR?

Ms Excel

- Excerpt from the Body of Knowledge for the CWI exam. Part B consists of 5 distinct areas of study.

For starters, WPSs and PQRs are the blueprints for creating welds in a repeatable, efficient, and safe manner. If you need more proof that WPSs and PQRs are a big deal, look no further than theBody of Knowledgefor the CWI exam. This document offers an approximate breakdown of the topics that are covered in each part of the test. Part B focuses on the practical application of inspection, and is widely referred to as the hands-on portion of the exam. You’ll notice that atleast28% of the Part B questions relate to Procedure and Welder Qualifications. In order to answer these questions, you’ll need to know how to read WPSs and PQRs, extract pertinent information from them, and make assessments based off that information. I can tell you that the CWI seminar instructors do a fine job covering WPSs and PQRs from firsthand experience. However, if the first time you lay eyes on a WPS is during the CWI seminar, or worse yet, the CWI exam itself, you’re really digging yourself into a hole.

Pro tip: If this is ringing especially true for you, feel free to check out the sample WPSs and PQRs in theAWS Book of Specifications.They can be found in the annexes toward the tail end of the document.

How Do I Use a WPS and PQR?

That’s a great question. It’s also one that warrants considerably more time and detail than I can provide in this venue. As I mentioned earlier, WPSs and PQRs are covered rather extensively during the live CWI seminars. However, if you’re looking to get a leg up, then you may want to consider AWS Learning’s “WPS/PQR: Explained” interactive online course. This course was created in response to continued feedback from students and educators, and covers the ins and outs of welding procedure specifications and procedure qualification records. This includes everything from what their purpose is, how they are drafted, what kinds of information they contain, and how to make use of that information.

The course also covers the procedure qualification process, including detailed information on material properties as well as common nondestructive and destructive tests. The instruction throughout this course is presented in a series of short modules, allowing you to internalize information bit by bit, instead of all at once. Each module builds on concepts introduced in the previous one, and includes quizzes and interactive practice questions to help you really get a grasp of the material.

So, Now What?

It’s important to keep in mind that we’re just scratching the surface here. WPSs and PQRs are an important part of a CWI’s knowledge base, but they’re far from the only thing. With that in mind, if you’re ready to take the next step and learn more about WPSs and PQRs, be sure to check out the“WPS/PQR: Explained”page at AWS Learning. While you’re there, you may want to check out some of our other educational offerings as well. Whether you’re looking to learn about a new topic, or brush up on one you’re already familiar with, AWSL’s suite of online courses is a great place to start.

Excel Spreadsheet

As always, if you have any questions, or if you have a suggestion for a topic you’d like us to discuss in an upcoming blog, give us a call or drop us a line in the comments section below!